Breath Easy: How Pressurised Cabins Shield Operators from Asbestos Hazards

In the dynamic world of heavy plant machinery, where safety is paramount, the threat of asbestos exposure remains a persistent concern. Asbestos, a naturally occurring mineral once extensively used in construction materials, poses severe health risks when its fibers become airborne. Heavy machinery operators are particularly vulnerable, working in environments where asbestos-containing materials may be present. To address this challenge, innovative solutions like Cabin Re-Breathing Machines have emerged, providing a crucial layer of protection for operators.

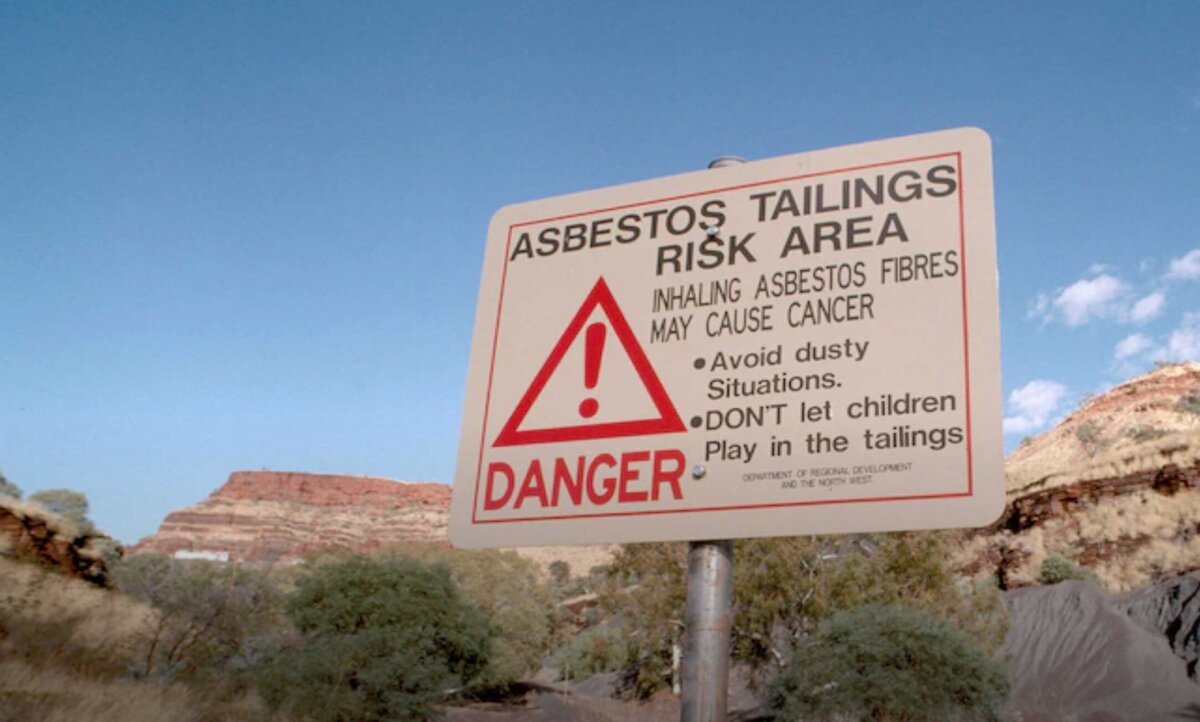

The Largest Contaminated Area in the Southern Hemisphere

When KEE Group collaborated with Austral on the Koodaideri Project located at Rio Tinto’s Pilbara mine, both companies made health and safety their number one priority. This is because the mine is in close proximity to Wittenoom, which is recognised as the largest contaminated area in the southern hemisphere. Both KEE Group and Austral maintained a heightened state of vigilance to ensure the safety of their workforce in the face of potential asbestos hazards.

During the project execution the companies successfully deployed Cabin Re-Breathing Machines across the site. This strategic initiative was undertaken to prioritise and enhance the health and safety standards for all operators involved in the project.

Understanding the Asbestos Threat and the Vital Role of Pressurised Cabins

Asbestos exposure can lead to serious health issues, including lung diseases and cancer. Recognising this risk, heavy plant machinery companies, such as Austral and KEE Hire are increasingly turning to advanced technologies. Cabin Re-Breathing Machines stand out as a powerful defense mechanism, pressurizing cabins to prevent the infiltration of asbestos-laden air. This subtitle delves into the inherent dangers of asbestos, emphasizing the importance of proactive measures to safeguard operators.

In asbestos-rich environments, heavy machinery operators face a dual challenge—managing complex equipment and mitigating health risks. The understanding of how asbestos becomes airborne and the potential consequences for operators underscores the urgency of adopting innovative solutions. Cabin Re-Breathing Machines not only serve as a protective barrier but also contribute to creating a secure working environment.

Enhancing Operator Safety: A Deep Dive into Cabin Re-Breathing Technology

The heart of the matter lies in the technology driving Cabin Re-Breathing Machines. This subtitle takes a comprehensive look at the mechanics behind these systems. By maintaining positive pressure within the cabin, these machines effectively create a barrier against external contaminants, including asbestos fibers. Examining the intricacies of this technology sheds light on its efficiency in ensuring operator safety.

Incorporating advanced filtration systems and real-time monitoring, Cabin Re-Breathing Machines exemplify a proactive approach to safety. Operators can now navigate their heavy machinery tasks with confidence, knowing that their cabins serve as secure, controlled environments. This deep dive into the technology emphasizes the transformative impact of pressurized cabins in the realm of heavy plant machinery.

Choosing Wisely: Factors to Consider When Implementing Asbestos Containment Measures

Implementing Cabin Re-Breathing Machines requires a strategic approach. This subtitle guides heavy plant machinery companies through the decision-making process, offering insights into the factors that should influence their choice. From assessing the specific risks in a given environment to considering the ease of integration with existing machinery, making informed decisions is critical in ensuring the success of asbestos containment measures.

Choosing the right Cabin Re-Breathing Machine involves a synergy of technological compatibility, regulatory adherence, and operational feasibility. This subtitle equips decision-makers with a roadmap, enabling them to navigate the myriad considerations involved in adopting innovative solutions. As heavy plant machinery companies prioritize the well-being of their operators, the importance of choosing wisely cannot be overstated.

The implementation of Cabin Re-Breathing Machines represents a paradigm shift in ensuring the safety of heavy machinery operators working in asbestos-rich environments. These machines not only shield operators from the potential health hazards of asbestos but also exemplify the industry’s commitment to embracing innovative solutions for a safer and more secure future.

photo credit: WA Today